NextGen Label Group (Syracuse, NY) is excited to announce a new licensing agreement with OPM Advance Limited (Part of OPM (Labels & Packaging) Group Limited) to bring TLC (Thicker Label Closure) technology to the North American wet wipe and flexible packaging markets. This patented* semi-rigid, peel-and-reseal label system provides a sustainable, high-performance alternative to traditional rigid flip-top closures.

Already adopted by major global brands and with over 80 million labels produced in 2024, TLC is redefining how packaging closures function—delivering on sustainability, manufacturing efficiency, and consumer convenience.

What is TLC?

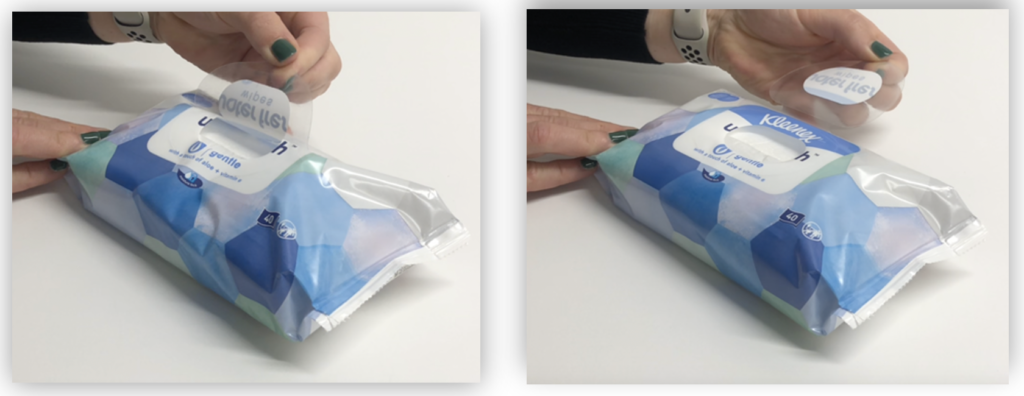

Patented in the U.S., Europe and in parts of Asia, TLC is an advanced label solution engineered to replace rigid plastic closures with a cost-effective and environmentally friendly alternative. TLC enhances the user experience with easy-to-open functionality while supporting faster production throughput and helping brands meet sustainability goals.

Key TLC Benefits

TLC offers a variety of product benefits as compared to traditional rigid flip-top lids including:

Sustainability Improvements

- Reduced CO2 Emissions – Lighter packaging allows for more efficient transport and decreased emissions along the entire supply chain.

- Eliminates Rigid Plastic – Replaces traditional lids with a single label solution.

Cost Efficiency

- Reduced Shipping Costs – Lighter packaging lowers freight expenses.

- Optimized Storage – Less bulky packs maximize warehouse space.

- Reduced Manufacturing Costs – TLC labels cost less than rigid-top closures and require no secondary labels.

Brand Continuity

- Enhanced Print Capabilities – TLC labels print in up to 10 colors. Specialty finishes and enhancements to maintain consistent brand presentation with established guidelines and standards are available.

Enhanced Consumer Experience

- Moisture Retention – TLC labels retain moisture in the pack better and longer than rigid flip-top lids.

- Easy to Use – Simple open and reseal functionality enhances user satisfaction over rigid-top closure products.

Streamlined Production

- Compatible with Existing Manufacturing Lines – TLC labels are applied on standard packing lines. No additional processes such as welding or glueing are needed, increasing manufacturing efficiency and reducing waste.

Indirect Cost Savings

- Brands can benefit from reduced labor and material costs, leading to significant savings across the supply chain.

With this TLC Licensing Agreement, NextGen Label Group reinforces its commitment to solutions-driven innovation and brand custodianship. This innovative label is a revolutionary solution for brands in the wet wipes and flexible packaging markets. Sustainability, cost savings, brand continuity and consumer convenience are just some of the benefits to be gained.

For more information on how TLC can help your brand, please visit nglabel.com or contact Georgina Webb at (603) 400-0980 or gwebb@nglabel.com.

*US Patent #10730677, US Patent #11667448, US Patent#11999548, EU Patent #3256398, UK Patent #GB2539331, UK Patent #3256398, Japan Patent #6859333, Hong Kong Patent #1236172, Hong Kong Patent #1243047